Small-Volume Piston Provers

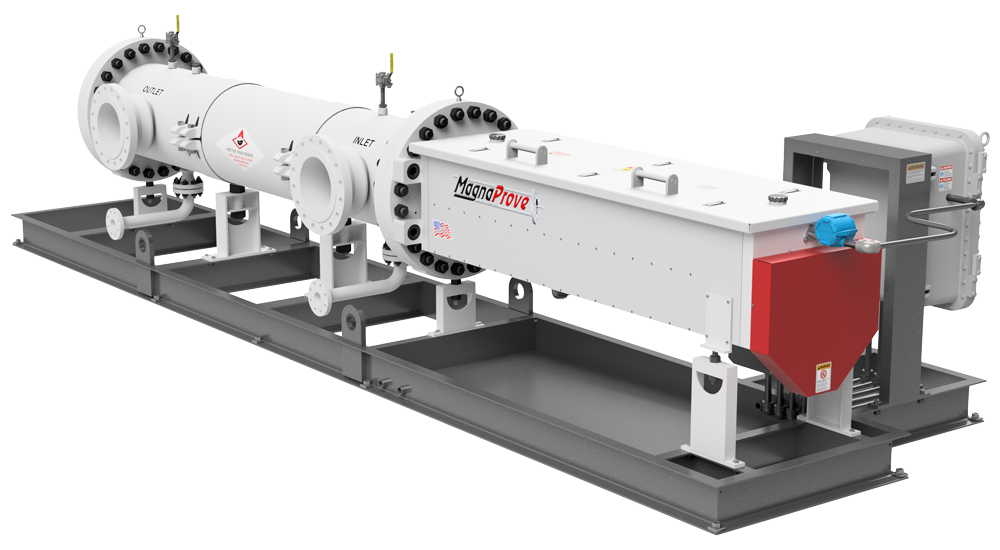

MagnaProve® Overview

The Future of Captive Displacement Prover Technology

Meter Engineers’ new, patented MagnaProve® is the most dependable, user-friendly, and economical small volume piston prover on the market. Accuracy is not a want or a need. It’s an expectation. For the petroleum industry, a small metering error can create an enormous dent in profits. With the new MagnaProve, accuracy and dependability contribute to a healthy bottom line. This meter prover is designed for precision and durability while remaining flexible and versatile for a wide range of metering sites and applications.

Features at a Glance

Exclusive Unique Drive System with A High-Strength Electromagnet

Why the magnet? It was the lure of building a better product. The world needed a prover with superior flow rate turndown, faster cycle times, and improved system durability. From these aspirations, we developed the MagnaProve, the only meter prover to utilize the power of the magnet. This proprietary electromagnet design with a linear actuator gathers its performance by releasing the piston from the magnet, which removes drag from proving runs. This drastically boosts efficiency and proving cycle times. In fact, the linear actuator provides prover readings in as little as 5-second intervals, depending on the flow rate. Equally important, the magnetic field does not transfer through the stainless-steel internal parts. This ensures no extra debris is picked up that would affect the accuracy of proving readings. Additionally, the stainless-steel casing prevents electromagnetic field interference to the system, allowing the magnet and piston to perform their duties unencumbered. All things considered, who wouldn’t be attracted to a prover that delivers this level of system certainty?

- Exclusive inline magnetic drive system

- Efficiency contributes to a healthy bottom line

- Improved system durability means less downtime

- Drag is significantly reduced for faster cycle times

- World-class factory service and support

- Options include: Custom engineered trailers, truck beds, load arms, swivel joints, spring assist, seal check, leak detection, pycnometer, custom density packages, and much more

- Inlet and Outlet Orientation Configurable Upon Request

- All models are capable of portable and stationary options.

Which Model Do I Need?

MP1050

change model

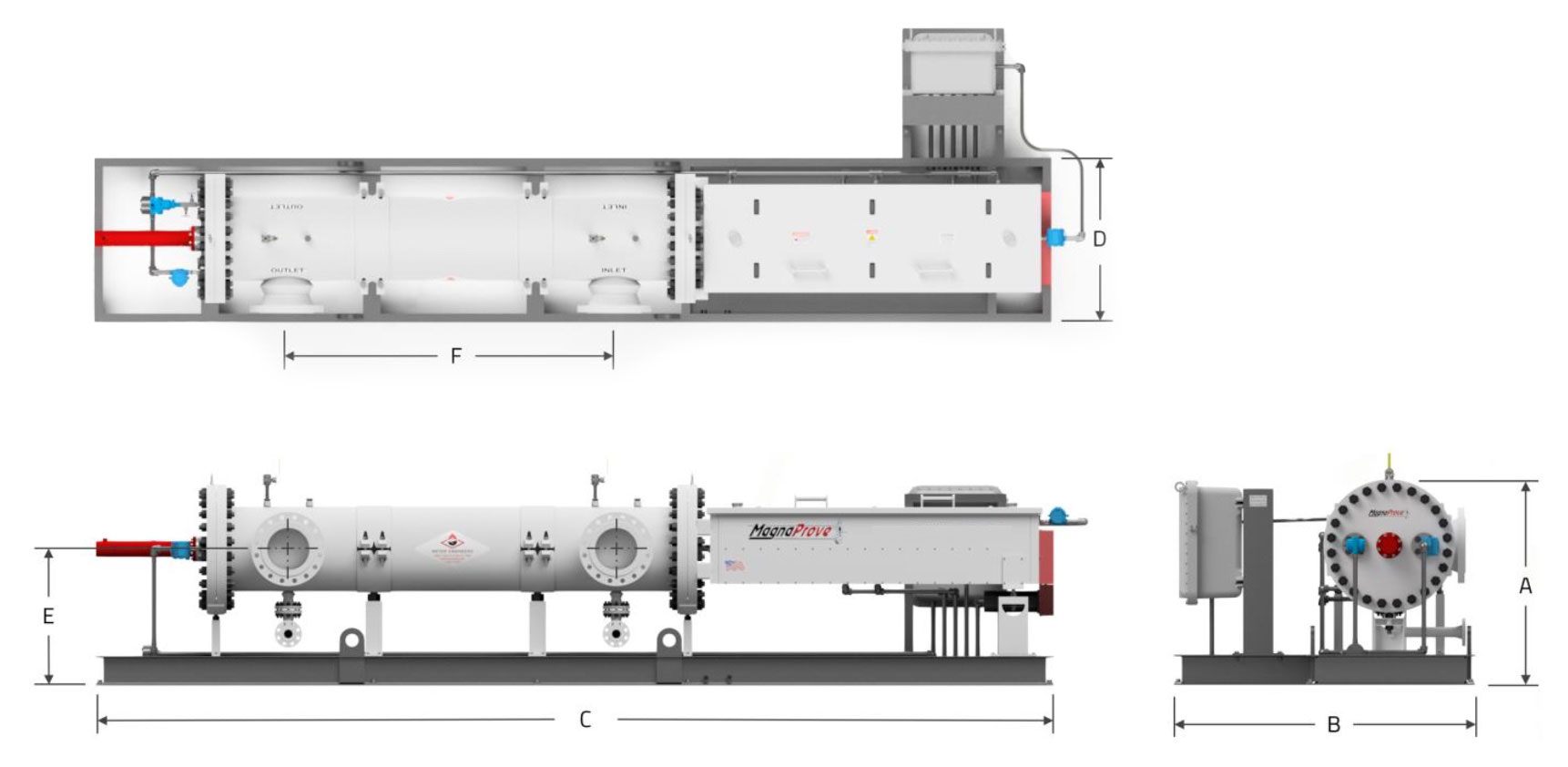

Dimension

Spooled – IN (CM)

Spoolless – IN/CM

A 35 (89) 35 (89) B 49 (124) 49 (124) C 185 (469) 181 (459) D 31 (79) 31 (79) E 23 (59) 23 (59) F 66 (167) 54 (136) Note:

1. Dimensions are subject to change based on the ANSI flange pressure rating.2. All dimensions are subject to change without notice.

Inlet/Outlet Front Side

36in / 91cm Guide Rod

144in / 366cm Barrel Back Side

24in / 61cm Cabinet End

96in / 244cm Electrical Box

36in / 91cm

Spooled

ANSI B16.5

Flange RatingWeight (+/- 5%)

Weight w/ Water (+/- 5%)

Class 150 1520lbs / 689kg 1608lbs / 762kg Class 300 1790lbs / 812kg 1950lbs / 885kg Class 600 2250lbs / 1021kg 2410lbs / 1093kg Class 900 2880lbs / 1306kg 3040lbs / 1379kg Spoolless

ANSI B16.5

Flange RatingWeight (+/- 5%)

Weight w/ Water (+/- 5%)

Class 150 1400lbs / 635kg 1520lbs / 689kg Class 300 1560lbs / 708kg 1680lbs / 762kg Class 600 1810lbs / 821kg 1930lbs / 875kg Class 900 2150lbs / 975kg 2270lbs / 1030kg

ANSI B16.5 Flange Rating

Max Working Pressure (PSI)

Class 150 285 Class 300 740 Class 600 1480 Class 900 2220 Note:

1. Max working pressure is rated for a temperature range of -20°F(-30°C) to 250°F(120°C). Per ASME/ANSI 31.4 para 404.4.12. All pressure-containing welds have been NDT tested per ASME/ANSI 31.3.

Max Flow Rate

735 GPM / 1,050 BPH / 167 M³H Displaced Volume

5Gal / 19L I/O Size

3in Turndown

1200:1

120VAC Single-Phase 120VAC / 240VAC Single-Phase 240VAC Three-Phase 480VAC Three-Phase

| Model Number | Size (O.D.) | Displaced Volume (GAL) | Max Flow Rate (BPH) | 1 SECOND FLIGHT TIME MAX FLOW RATE (BPH) | STD. I/O Size |

|---|---|---|---|---|---|

| MP1050 | 8" | 5 | 1,050 | 437 | 3" |

| MP1300 | 14" | 10 | 1,300 | 857 | 3" |

| MP2600 | 14" | 15 | 2,600 | 1,286 | 4" |

| MP4500 | 18" | 30 | 4,500 | 2,571 | 6" |

| MP5355 | 20" | 35 | 5,355 | 3,000 | 8" |

| MP8500 | 25" | 65 | 8,500 | 5,571 | 10" |

| MP12750 | 29.5" | 100 | 12,750 | 8,571 | 12" |

| MP18500 | 36" | 150 | 18,500 | 12,857 | 16" |

| MP28500 | 46" | 250 | 28,500 | 21,429 | 20" |

Downloads

Your access to full specifications, product brochures, operation manuals, and more. Want additional information? Sign up below to be the first to know!

Have Questions?

Product Support

From our floor to in-the-field, Meter Engineers products are manufactured and supported with rigorous detail. We proudly stand behind our products as a world-class support team; ready to assist customers when and how they need it. We are here for you.

Sales Inquiries

Do you need a metering solution for a specific application or flow rate on a job site? Or perhaps, you are looking for a custom prover product that delivers accuracy and dependability, but needs to adhere to some unique requirements? Contact our sales team, today!

Let's Stay In Touch

Meter Engineers continuously strives to develop the most innovative solutions for the Petroleum Industry and our customers. Sign up and be the first to know about products, services and support because exciting news is always worth sharing.