Load-Assist Technology

Load Arm Assist Overview

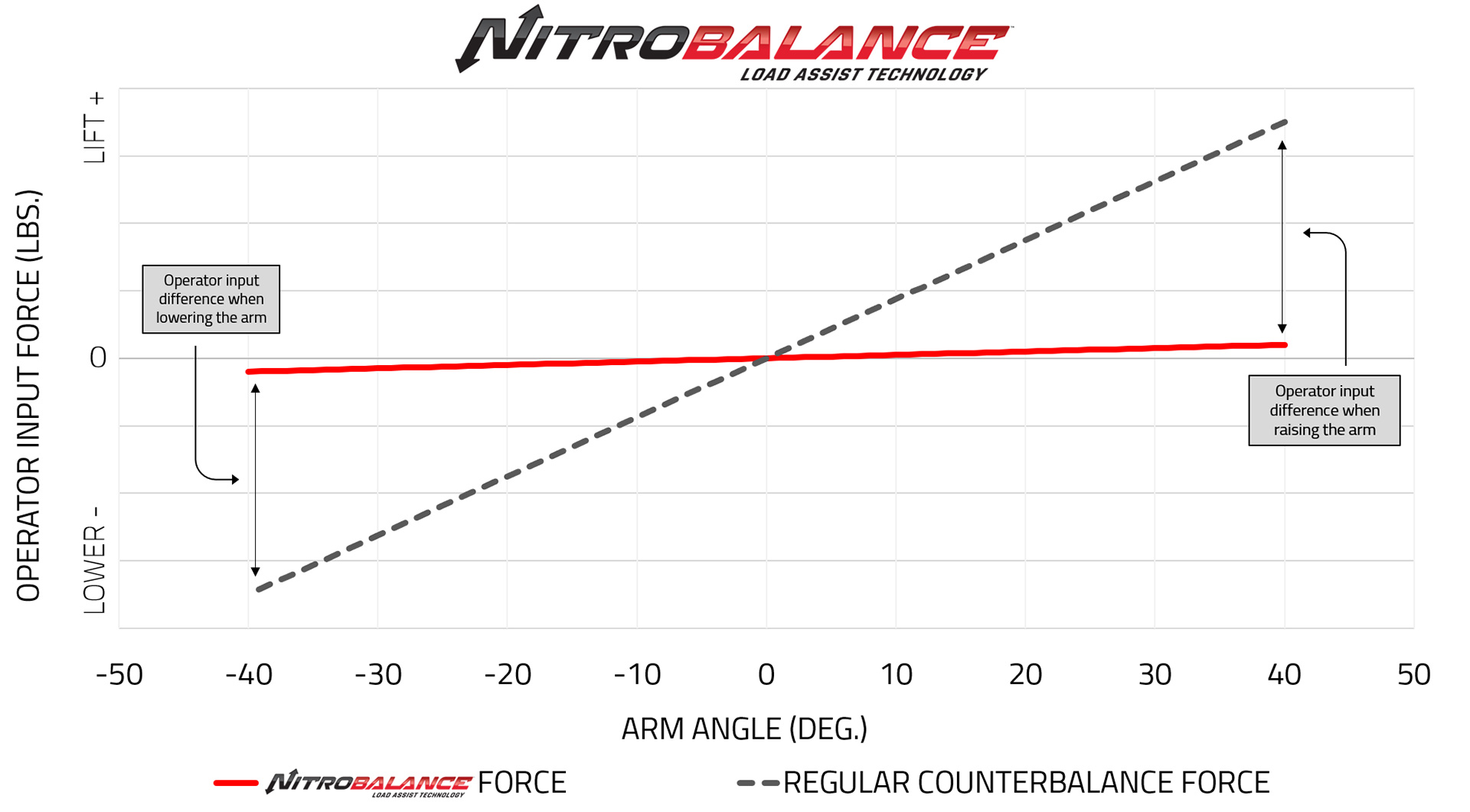

Meter Engineers’ new Nitro Balance™ spring assist canisters are the most versatile and dependable load arm counterbalances on the market today. Forget your worn-out coil or torsional spring canisters. Nitro Balance™ canisters utilize heavy-duty gas springs arranged in a parallel configuration. These gas springs provide a much lower spring rate than can be achieved with any other style of spring while still providing a high enough force to hold the entire mass of the arm. Load arms need a canister with a low spring rate so that the operator can effortlessly move the arm to any position throughout the entire range of travel. The biggest issue with coil or torsional canisters is that the force in the canister increases much faster than what the arm needs to be held in equilibrium, so the operator must fight the canister to move the arm when instead the canister should be doing all the work.

Features

Nitro Balance™ gas springs are filled with a specified nitrogen pressure from the factory to exactly match the force needed for your loading arms. This is a very cost-effective way to get a completely custom spring canister that is perfectly tuned for your arms. Meter Engineers engineering department will help size a custom canister to fit all your needs.

Benefits of NITRO BALANCE™

- Load arms need a low spring rate to be in equilibrium. At all locations through the travel, nitrogen gas springs can provide a much closer rate to the required arm rate than a coil or torsional spring can achieve.

- Since the rate of a nitrogen spring is based on the canister volume, the canister volume can be sized to match the rate needed by the arm. A mechanical spring rate is based on the material properties and has binding limits, unlike changing the volume of the gas.

- Standard spring assists use mechanical springs that must be compressed to get to their installed length for the needed arm equilibrium force, where the gas springs installed length is also their free length, and the vital force is already set into the gas spring. This makes the assembly and maintenance much easier and safer.

- Once the mechanical spring is in the canister, a considerable amount of energy is stored, even at the installed height. But with a gas spring, all energy is stored within the gas spring and not on the canister. Meaning when the gas spring returns to the installed height, the canister retains no energy, allowing the canister to be greatly simplified and much smaller than a traditional canister.

- Since the gas springs have their canister with threads, they are easily attached for solid and safe mounting, unlike a spring usually sandwiched inside the canister.

- The gas springs can be made to any diameter and length to accommodate the force, rate, and stroke needed to fit each individual load arm application.

Downloads

Want additional information? Sign up below to be the first to know!

Have Questions?

Product Support

From our floor to in-the-field, Meter Engineers products are manufactured and supported with rigorous detail. We proudly stand behind our products as a world-class support team; ready to assist customers when and how they need it. We are here for you.

Sales Inquiries

Do you need a metering solution for a specific application or flow rate on a job site? Or perhaps, you are looking for a custom prover product that delivers accuracy and dependability, but needs to adhere to some unique requirements? Contact our sales team, today!

Let's Stay In Touch

Meter Engineers continuously strives to develop the most innovative solutions for the Petroleum Industry and our customers. Sign up and be the first to know about products, services and support because exciting news is always worth sharing.